Higgstec T121S-5RBE18N Touch Screen Panel

- Model

- T121S-5RBE18N

Item specifics

- Warranty

- 365 Days

- Shipping

- DHL/FedEx/UPS/TNT/EMS/Aramex /DPEX

- Touch points

- Single-touch

- Place of Origin

- China

- HMI touch glass

- touch digitizer glass

- HMI panel glass

- touch screen monitor

- Name

- T121S-5RBE18N Touch Screen Panel

Review

Description

Higgstec T121S-5RBE18N Touch Screen Panel

T121S-5RBE18N touch screen

T121S-5RBE18N touch panel

T121S-5RBE18N Touch screen glass

T121S-5RBE18N Touch screen hmi

T121S-5RBE18N touch memrbane

T121S-5RBE18N touch digitizer

T121S-5RBE18N touchscreen

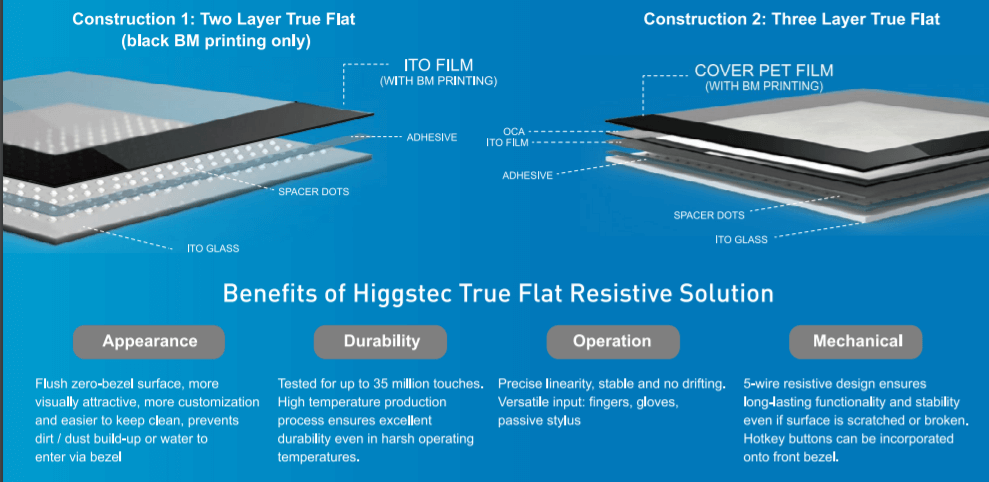

True Flat Resistive Touch Solution

Our True Flat Resistive touch solution combines the simplicity, versatility and durability of our 5-wire resistive technology with an attrac- tive zero-bezel desian.

The fush surface is easier to clean and there will be no dust or dirt buildup or water leakage into the bezel, making it an excellent solution for sterile or dust free environments such as medical dinics, scientific laboratories, restaurants or food processing areas. What's more, you now also incorporate features such as logos or hotkey buttons on the cover design".

Higgstec also uses a special high temperature production process for its resistive screens to fuse the silver sensor circuit onto the glass, preventing it from peeling off during extreme temperature or humidity variations, ensuring greater longevity and durability in harsh operating environments

A front cover shield (glass, fiberglass, PMMA or other material) can also be added to the front of the resistive panel for anti-abrasion and chemical resistance protection.

FAQ:

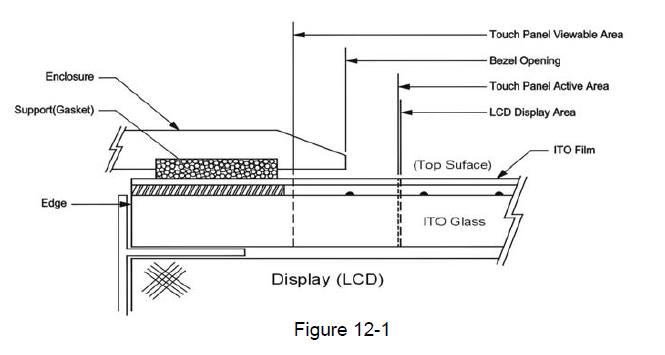

Question:Attention of Mounting Condition

Answer:

(1) The gasket support of touch panel must allocate outside of

Viewable Area. Reserve enough clearance between panel surface

and enclosure for normal panel operation.

To avoid pressing error, please retain enough space between

surface panel and Bezel.

(2) Bezel opening must not touch Viewable Area, Bezel opening must

be designed between Viewable Area and Active Area.

(3) We recommend elastic material support.

(4) Due to the conductive characteristic of the panel backside, prevent

metal contact after mounting.

(5) Do not use adhesive to bond top surface (ITO Film) of touch panel

with enclosure.

(6) Proper grounding of controller at all times assure normal operation.

(7) During assembly. Please take into consideration the variance in the

different module designs, whether it would cause physical,

cosmetic or functional damages to the touch panel, when

completing the assembly.

(8) After installation,please perform 4 point and 25-point calibration.